The Panel Schedule template is related to the information concerned with the electrical panel box. Mostly electrical engineer uses it to check the supply of electricity in a building. Moreover, you can download free templates and fill in the details for recording the information on an electrical panel. You can use it in word or excel formats. An electrical panel is made up of a metal box. Its location is near to the door with a built-in wall along with an out-of-the-way corner of the house.

What is a panelboard Schedule?

Electrical specialists utilize an electrical board plan template to make a panel board plan. It is a basic timetable utilized by electrical specialists to plan different projects and to decide how much power is required for their installation and operation.

Electrical designers utilize a panel board timetable to survey over-burden issues and introduce the pertinent safety systems. Power plans give precise documentation and design for electrical machinery. A usable panel schedule template can be made before interfacing or in the wake of connecting circuits.

An electrical panel schedule template is utilized as the need might arise to distinguish which machine needs power. It is unique concerning an equipment schedule because the last option guides the sort of wiring and power expected for specific equipment in terms of ampacity, volts, or phase.

In a bustling commercial site, there are typically a ton of panels of importance there are likewise a ton of schedules to manage. The electrical technician ought to be quick to distinguish accurately which panel powers which equipment or machine.

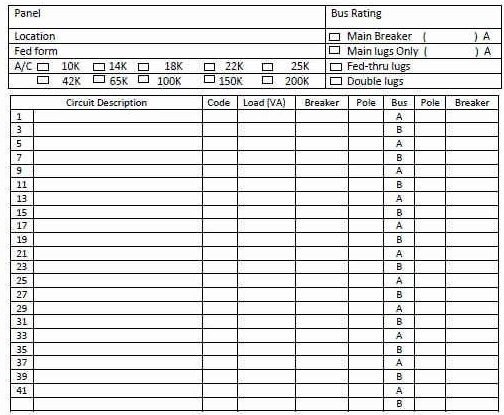

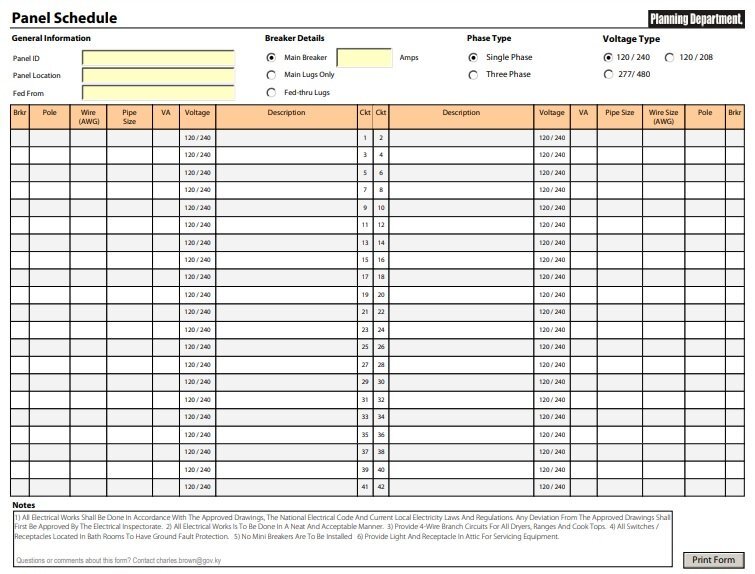

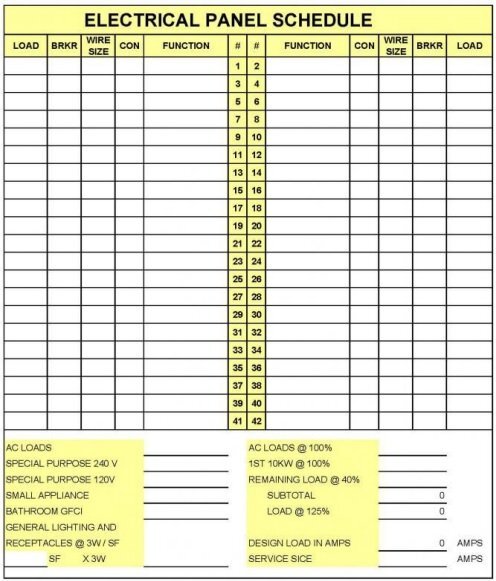

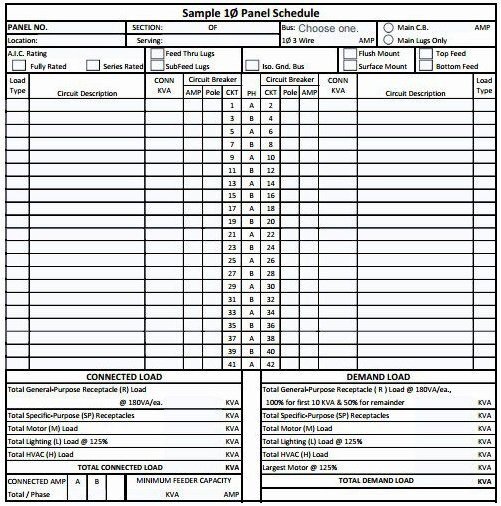

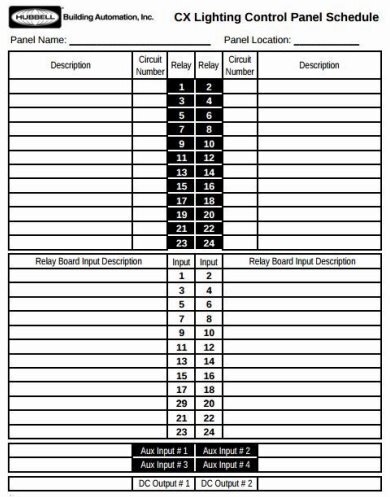

Panel Schedule Template:

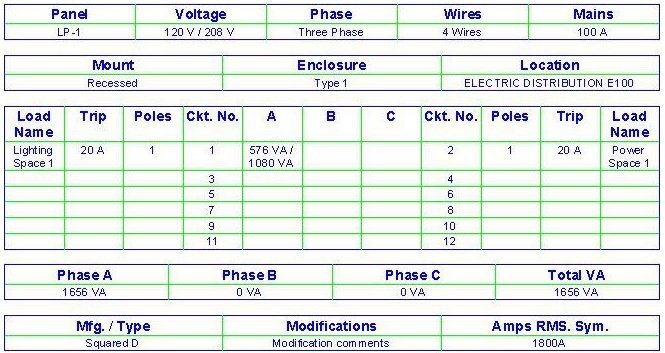

A distribution board consists of components of an electrical supply system. It divided an electrical power feed into subsidiary circuits. Moreover, it provides a protective fuse or circuit breaker for each circuit in a common enclosure. All circuit breakers supplying electricity in the different rooms of the house, apartment or building are present in the power panel. For electrical panel related information, you can find it free on the internet. There are also different formats like word, excel and pdf where you can record information. Different tools are also available through which you can check the load of each circuit breaker located in the electrical panel.

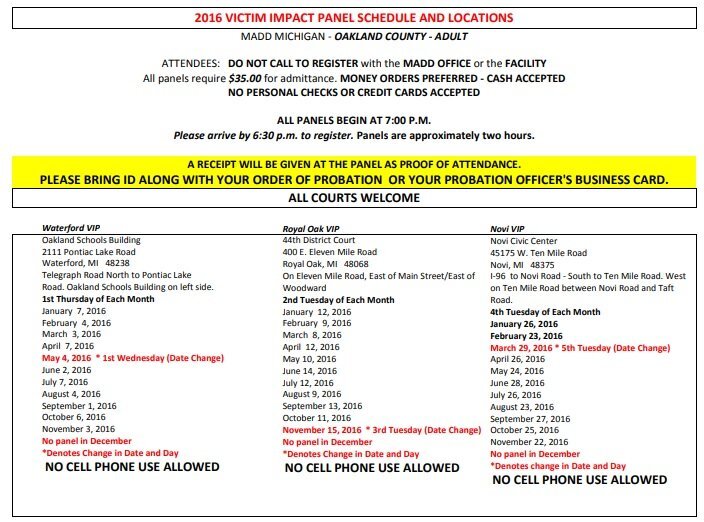

victim impact panel schedule template

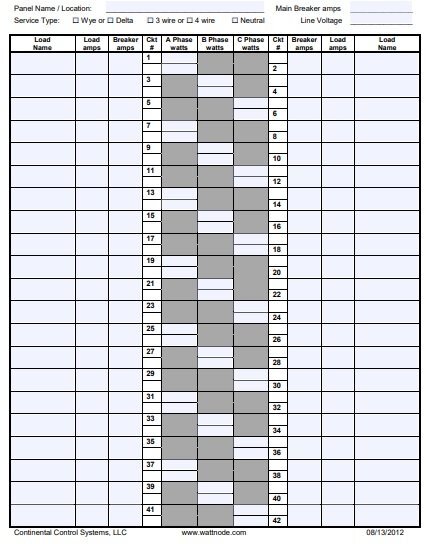

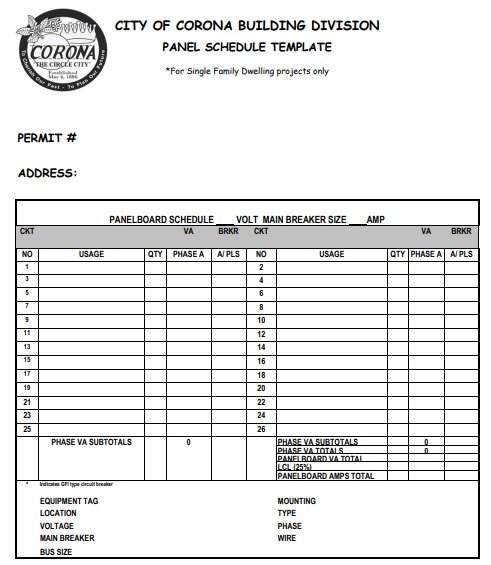

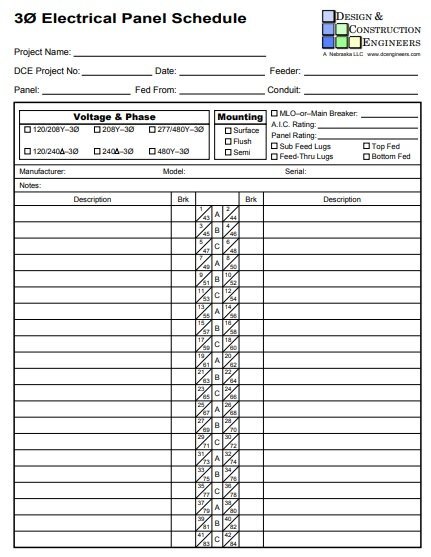

three phase panel schedule template

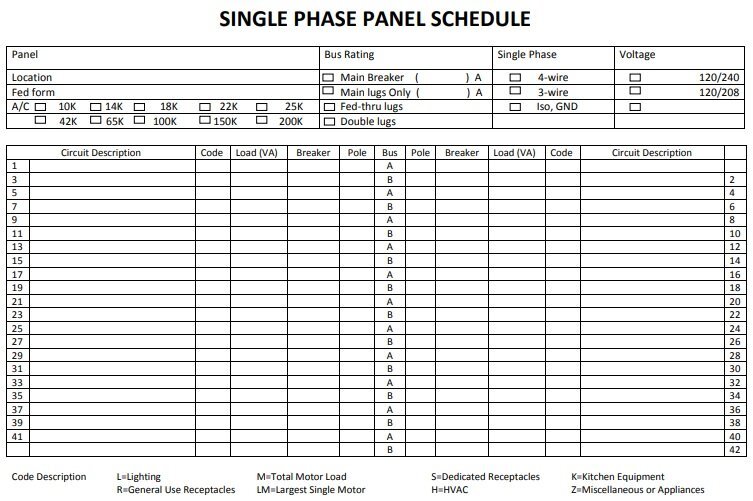

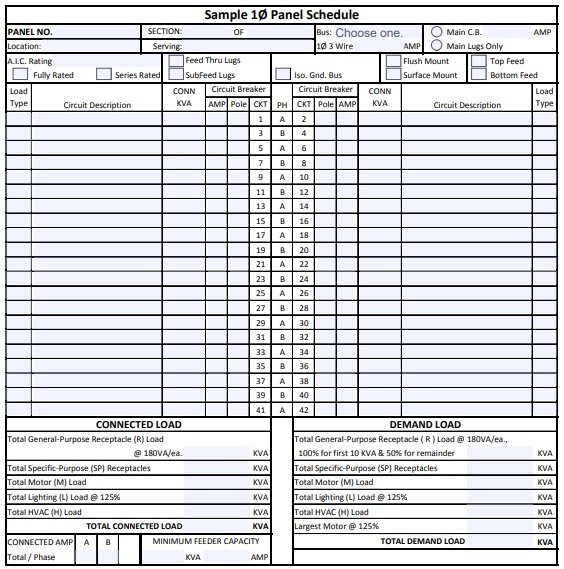

single phase panel schedule template

siemens electrical panel schedule template

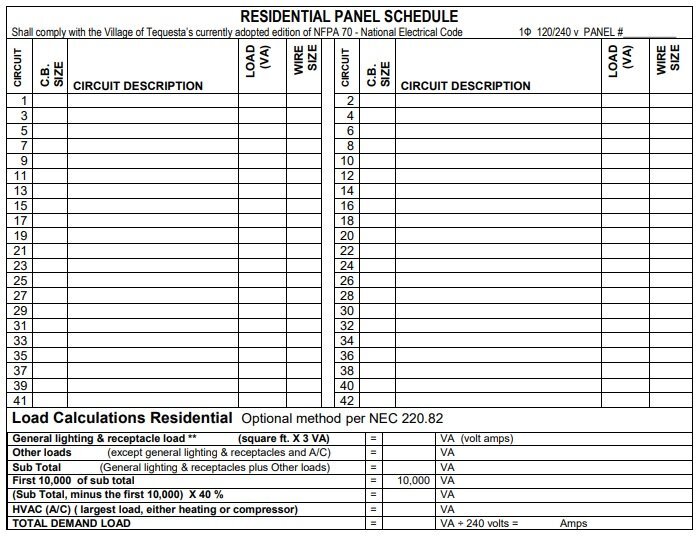

schedule for residential panel template

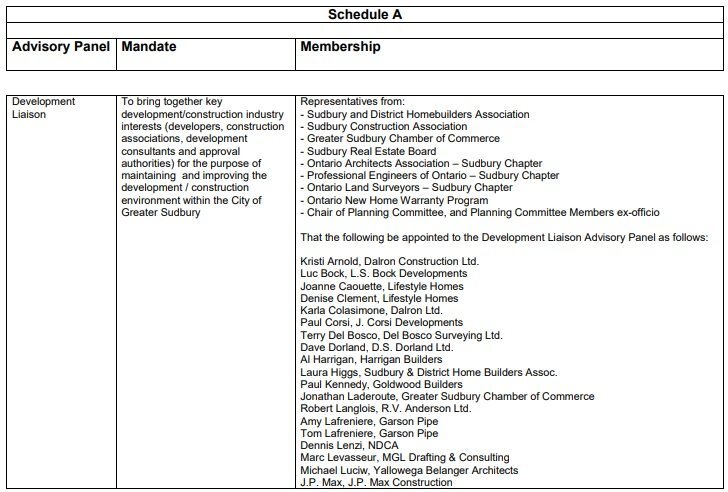

schedule for advisory panel template

panel upgrade schedule template

printable panel schedule template

printable panel schedule template 1

What does a panelboard Schedule show?

At the point when an electrician is new to a business site, the principal thing they ought to demand is the fillable panel schedule template that shows the subtleties of boards and machine connections. The panel board will direct them by showing these subtleties.

Equipment name

These include apparatus, appliances, cables, conductors, insulators, motors, pumps, poles, fans, and so forth.

Circuit number

The circuits can be given any numerical digit however keeping away from confusion should be one of a kind. The numbering should be possible as per the segment the circuit serves. A circuit is essentially a power connection from point A to point B through which power can flow. Circuits are made of wires of various sizes relying upon how much power is required.

Circuit breaker size

Contingent upon which equipment the breaker has served, some of them are large while others are little concerning amperes. The littlest can be 2 amps while the biggest can be 32 amps, 1000 amps, 5000 amps, or more.

Circuit breakers for lighting circuits are little however those that serve cookers, coolers, or water warmers are enormous because the appliances require more amperes/voltage. Breaker size assists electrical experts with choosing the size of wires to utilize.

Number of poles/stages

A pole or a phase implies the all-out isolated circuits constrained by a switch. Generally, poles can either be single or double. A solitary post switch is relegated to one circuit while a double shaft is doled out two circuits inside a similar button. Truly, these are two separate circuits joined to one button. A few poles are three-post breakers requiring three-stage power.

Significance of panelboard schedules

Making work simpler

Panel schedules can be made from an excel panel schedule format. Without the schedule, an electrical technician can’t fix the electricity framework in a site successfully. It helps guide them from point A to point Z at the stage when they are pulling wires.

The electrical expert alludes to the usable board plan format to sort out which devices will be served by the wiring while at the same time limiting the number of pulls however much as could reasonably be expected.

Assessing the right electrical load

There are times when power use is at its pinnacle, particularly at night, end of the week, and on holidays. An electrician ought to accurately gauge how much electrical load is during this time and the normal hours of the day. The subtleties contained in an electrical panel schedule format assist them with computing their estimates accurately.

Adding additional loads

A site or facility could expect to be extended from now on. They may likewise require adding additional loads because of the requirement for additional gadgets. Without the subtleties in a fillable panel schedule template, the owner could over-burden a few circuits and influence the breakers, sockets, main supply, or wiring.

Permitting future expansion plans

At the point when there is a requirement for development, the electrical expert purposes the panel schedule to prompt the owner on which circuits will supply the extension. It maintains a strategic distance from power risks because of overworking a single circuit.

Better power the management techniques

A panel schedule gives a power management technique to keep power load adjusted in the periods between peak and off-peak hours. The home of the office owner benefits from keeping power costs controlled and subsequently sets aside cash consistently.

Installation of the right control situation

Electrical engineers utilize the subtleties in an excel board panel schedule to choose the size of control frameworks, conduits, and conductors to purchase for installation. It assists them with planning the foundation for future burdens.

Without the appropriate arrangement of future loads, a whole electrical system should be redesigned to permit updating for obliging additional loads. Without this activity, there could be risks of fire, successive breaker tripping, machines neglecting to work, and so forth.

Prevention of accidents

The wellbeing norms set by OHSA expect organizations to finish up their electrical panel schedule format toward the beginning of the power establishment process. They ought to likewise plan the extra breakers that are not being used by naming them extra and keeping them switched off.

It is hazardous to keep an extra breaker on or to switch off a breaker when it is on. Having an accurately filled panel schedule template can assist with forestalling an electrical mishap in work environments and homes.

Labelling equipment

A fillable panel schedule template assists circuit repairmen with labelling gear accurately. They name the breakers, circuits, posts, and so forth. At the point when the equipment is named accurately, it saves business time spent going through the power system to distinguish how the circuits are running. It likewise works on electrical safety inside the office.

Avoiding dangers from spare power breakers

Spare breakers ought to be marked accurately as extra and numbered appropriately. Without labelling them, someone could expect they ought to support a specific circuit and switch them on. By switching them, they will hinder the power flow which could lead the property harm by electrical fire or machines harm because of overloads or surges.

How to make a panel schedule?

To make a point-by-point panel schedule, you may initially download a panel schedule guide to assist you with understanding the subtleties you require. The panel schedule example can be Excel or some other document design. Here are the moves toward following while making a panel schedule.

List all loads in the whole installation

Electrical loads mean electrical components that are consuming power inside the facility. At the point when an electrical flow arrives where it is changed into alternate energy, that point is known as a load. It tends to be changed into light through an electric bulb, heat through a heater, turn a motor, or charge a battery.

Determine the loads

In the wake of posting the loads, determine each sort of load. There are various sorts of loads.

Resistive loads- transform power into heat by opposing its flow. A model is lights and warmers.

Inductive – they change electrical flow into attractive energy. Models are transformers, coils, and electric engines.

Capacitive – they store modest quantities of energy to drive a device. Examples are motors, radios, TVs, telephone circuits, and so forth.

Combinative – they join at least two sorts of energy to work. Examples are radio tuners, cathode beam tubes for TV or screens, and single-stage motors.

You can count the number of loads by counting the number of sockets and switches inside the office.

List the electrical properties of the loads- Each load is serving a particular machine that requires an exceptional number of amperes to work. A few loads require 6 amps, others 20, 100, 600 amps, and so forth. Consider factors like voltage, effectiveness, and so forth. Sort and name each load according to the amperes expected to serve it.

Categorize all equipment

Partition the equipment into classifications directed by the switchboard, load duty, and criticality. A switchboard assists with separating and distributing power into a few circuits. It contains a fuse for each circuit to offer protection to them. They can stack up to 600 V and disseminate power in a whole office.

Load criticality is estimated by the significance of equipment. A piece of equipment should be provided with the power to keep away from difficulties with the distribution. For instance, places like medical clinics, air terminals, and 911 focuses require basic loads. Figure out which region or load in an office is a basic burden.

Load duty implies the length of period when a specific load stays on and the time it stays off. A few loads should remain on constantly however others an on for a couple of hours in a day.

Decide the estimated measure of power each load will consume

A few loads will consume a modest quantity of force in any event, when they stay on for a long time. Others will be on for a brief time frame however consume a great deal of force. For instance, a lighting bulb will consume a modest quantity of power contrasted with a heater.

Kinds of electrical panel schedule templates

There are three fundamental sorts of electrical panel schedule templates as follows.

Branch panel schedule

This is an electrical panel schedule template that is utilized with a panel board device. A branch panel has three sorts of layouts that can be designed for various purposes.

- One section panel schedule

- Two sections’ circuits across the schedule

- Two sections circuit down schedule

Information panel schedule

It is a panel template utilized with an information panel device. It is utilized for recognizing circuits and information outlets. Gadgets that can be associated with a power panel are security cautions, alarms, telephones, and so on.

Switchboard panel schedule

It is a board utilized with switchboards. It shows subtleties of the board sheets associated with a switchboard.

What in all actuality do process and non-process loads mean?

While providing electrical loads during power establishment, you will make two kinds of electrical loads that are constrained by the load plan. A handling load is a load that relates straightforwardly to a building. They are generally associated with a structure’s mechanical equipment. These are loads, for example,

- Heaters

- Motors

- Conveyors

- Compressors

These loads are not working constantly but rather the second they are switched on, they consume a ton of power. Here and there it can assist an organization with setting aside more cash assuming they pick process loads that are energy saving. Similarly, they require thicker wires since they require more voltage and amperes to run or work.

Non-process loads

These are the loads that assist with making the building livable. Without the non-process loads, it very well may be difficult to work or live in such a building. These are loads like the control system, HVAC, utility system, lighting, fire security, and so forth.

These are loads that are working constantly yet contrasted with process loads, they consume lesser power. Notwithstanding, the combined power they consume in a month can make the bills take off high.

Consumed power

Each load will draw a specific measure of power whenever it is turned on. At the point when that drawn power is determined, it is called consumed power. Since you can’t promptly get how much-ingested power is drawn by the gadget, it is generally determined at a rate between 80% to 90%.

Effectiveness

Not entirely settled by how well an electrical device functions. It is impacted by how much power it gets and the sum that is changed into mechanical energy. By and large, the productivity of a load ranges between 80-95%. The remainder of the power is lost as intensity.

Power factor

It isn’t each piece of a panelboard that will be receptive constantly. Generally, just a piece of the load-up will be responsive at some random time. The responsive segments versus the non-receptive parts are known as the power factor. It is for the most part estimated according to every individual load.

The purpose of electrical panel schedules:

If you want to measure the flow of electricity at different parts of the house, apartment or building, then you need to record that information on the document. Moreover, this is related to the electrical supply during the installation of the electrical panel. Some other elementary use of the electrical panel is as follow:

- This is the job of an electrical panel to distribute the electricity to each circuit breaker.

- The distribution panel protects your electricity system from any overload issue.

- With the help of a panel schedule, you can track the power supply and estimate the load in different phases.

- Its use in commercial and industrial areas where there is a requirement of the accurate voltage of electricity.

- Moreover, It helps to manage the distribution of the power during working hours.

- Electrical schedule panels help you to make a better decision regarding a load of electricity.

- Through different checks of the electrical panel, you can reduce the risk of power failure in your home, apartment and commercial building.

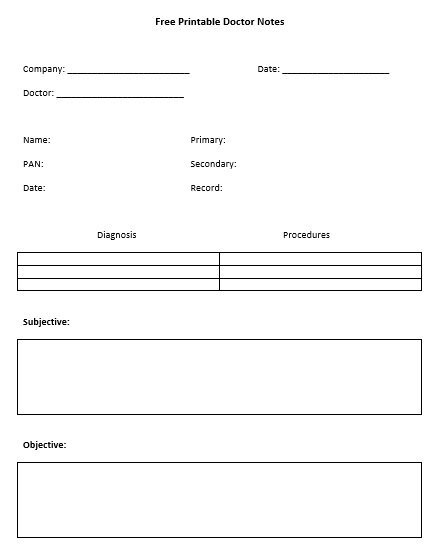

Key parts of the Panel Schedule Template:

It is important to check the flow of electricity in the commercial and industrial areas. Moreover, you can get the best design template with a few clicks. The best thing is it’s freely available. The different parts that makeup of electrical panels are as followed:

- Panel’s Location

- Panel Name

- Main power/Total voltage

- Short circuit current

- Number of wire used with name and type

- Number of circuit breakers

- Voltage type

- Phase type

- Load on each circuit breaker

The above information is mandatory to create an effective panel schedule. In our templates collection, you will see all the components covered completely. As a result, the use of our templates will help you to manage your electricity system efficiently.

printable panel schedule template 2

printable electrical panel schedule template

printable panel schedule template 3

panel report template

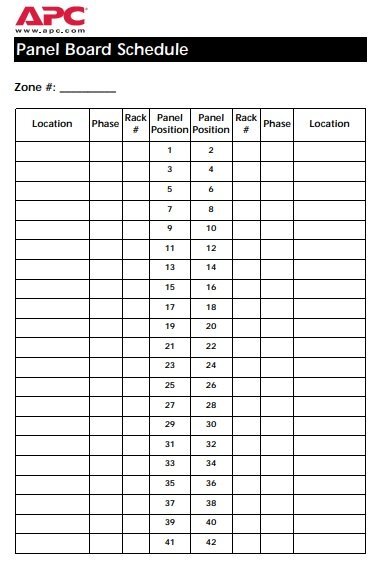

panel board schedule template

single phase electrical panel schedule template

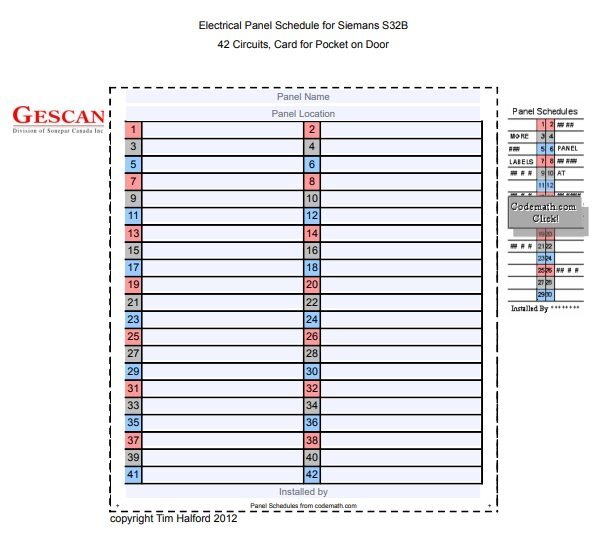

electrical panel schedule for siemens s32b2

electrical panel schedule form

circuit breaker panel label template

The Creation of Schedule Panel in Excel:

We provided you with the best details of fillable documents that are easy to use. If you want you can design your document with a few simple steps and excel is one of the best tools to create it.

- In the First step open Microsoft Excel.

- From the File menu, you will select new and a blank workbook will appear.

- Then the selection of the header. Go to the insert tab then click the “Text ” group arrow and select the header and footer option. Then give the name of your title “Panel Schedule”.

- Further, now you will write “Panel Name” and “Panel Location” after the title of this document.

- In Addition, you will make the first column of your document, you will go to the A1 Cell and write column heading as “Circuit”.

- Further, go to the B1 cell and write Column heading as “Size of Circuit Breaker”

- Further, you will make column header as “Load” that refers to the voltage and another column heading as “Wire size”.

- You will follow this pattern and add all the columns as per your requirement. This will help you to record the information.

- Go to the File tab and select the option “Save as ” and give the name of your file.

- Therefore, click ok and save.

Types of Electrical Panel:

There are four different types of panels that are common to use. These include the main breaker panel, fuse boxes, main lug panel and subpanel. Moreover, most of the residential people depend on their local electricity. The power comes from the utility company. It goes through the electrical panel which works as a distribution board. The mainboard distributes the load to each home as per their requirement. In Addition, this can be in the form of lights, appliances or any other devices which are in use by people.

- The main breaker panel is the main source of all the panels in your house. It regulates the supply of electricity and consumption in your house.

- Fuse boxes that contain small fuses, its function is to control overloading within your circuits.

- Main lug panels consist of the line wires that run into the lugs. They eliminate the need for the main breaker.

- Subpanels are electrical panels that their source of energy is from the main panel with a specific circuit. They control the man consumption of members of your household.

Do you know how many circuits install in your home? Similarly, Have you any information when you need to replace the electrical panel. The average duration of the panel is near about 20 years. You need to replace old electrical panels like fuse box which needs to update to one that is handling your current electrical consumption. However, if you experience flickering of light, the burnt smell from your electrical panel and frequent electrical trips. Moreover, you are adding more appliances or devices to your home. The advice is you should check your electrical panel with the electrical supervisor. As per his instruction, you can replace your panel as well.

Conclusion:

The panel schedule template contains information about the electrical panel box. Similarly, It is also famous for the name of the distribution box. Further, the current from your utility company comes to your distribution box and then load is delivered to your home as per consumption of different rooms. In Addition, if there is a flickering of electricity, trips of circuit breaker and burnt smell from the electrical wires.

Therefore, You should check your distribution box with your electrical supervisor of the local utility company. He will check thoroughly and recommend repairing or replacing the box. There are ready-made fillable templates available. With the help of these, you can check your load information and keep updating your panel schedule with circuit breakers.

![Free Delivery Schedule Templates [Excel, Word, PDF] truck delivery schedule template](https://cdn-ildebcd.nitrocdn.com/jnQCRkBozueuJprueOUxlAYnHGPdsTNY/assets/images/optimized/rev-d7007a4/templatedata.net/wp-content/uploads/2021/06/truck-delivery-schedule-template-150x150.jpg)

![12+ Free Rent Payment Tracker Spreadsheet [Excel, PDF] free rent payment tracker template 3](https://cdn-ildebcd.nitrocdn.com/jnQCRkBozueuJprueOUxlAYnHGPdsTNY/assets/images/optimized/rev-d7007a4/templatedata.net/wp-content/uploads/2021/10/free-rent-payment-tracker-template-3-150x150.jpg)

![20+ Free Printable Address Book Templates [Excel+Word+PDF] free address book template 12](https://cdn-ildebcd.nitrocdn.com/jnQCRkBozueuJprueOUxlAYnHGPdsTNY/assets/images/optimized/rev-d7007a4/templatedata.net/wp-content/uploads/2021/06/free-address-book-template-12-150x150.jpg)